Design

Mechanical Efficiency

Mechanical efficiency is of paramount importance in transmission engineering. This is true for the transfer and conversion of mechanical power as well as for the actuation of the gear shift mechanism.

In a modern and high tech manual transmission all elements for actuation of the internal gearshift are fitted with roller bearings to convey to the driver a true haptic impression about the gear change.

Naturally, the same requirement must apply for the external gearshift, for only then each phase of the synchronization process can be felt precisely in the hand guiding the gear knob.

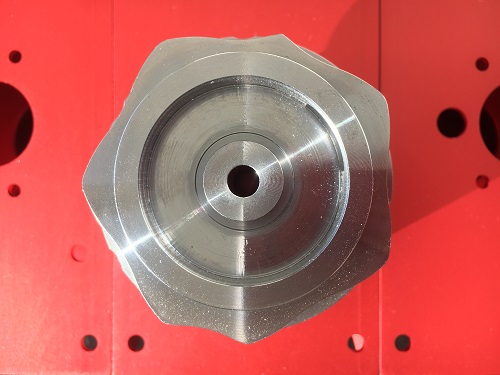

To achieve the highest mechanical efficiency all force-transmitting parts of the manalog race shifter are supported at their joints and guides by roller bearings. Thereby numerous ball bearings, needle bearings and combined linear-rotatory ball bearings are used which are exclusively supplied by renowned German manufacturers.

Package Space

One of the most precious goods in automotive engineering is space. Therefore the requirement for each component is to have a minimal size but also a shape suitable to fit into the free space available.

The manalog design family is structured in a modular way and allows therefore various configurations of which the one can be selected that meets the requirements of the targeted application best.

The demand for high mechanical efficiency as well as the criterion of robustness constitute a conflict of objectives regarding design space. The stronger each component is designed, the more precious space they are all consuming. Also a joint supported by roller bearings takes more room than a corresponding slide bearing concept.

For a given design space, therefore, a special mechanical function structure is required to achieve a design that fits and is able to withstand high forces and transmit them without losses.